Magna Rib

MAGNA RIB

- Pre-Painted!

- Full 36” net coverage. Normally 29ga.

- Purlin-bearing edge for strength while fastening side laps.

- Anti-siphoning side lap.

- 8 intermediate stiffening ribs add extra strength to this panel.

- Custom lengths 3’ through 40’0” in cut-to-length 1” increments.

12” or 16” Loc Seam

- Low maintenance and easy installation

- Residential / Architectural application

- Direct fastened – no clips necessary

- Installed over solid substrates w/felt or synthetic underlayment

- On – site roll forming

- No exposed fasteners

- OPTIONAL: Beads or Striations

ClipLoc Standing Seam

- Our ClipLoc panel is a snap-together panel – no seaming required!

- They are engineered to exceed most wind load requirements in the country while enhancing the aesthetic appearance of a building, whether residential or commercial.

- 24 ga. Pre-painted Galvalume (22 gauge optional).

- .032/.040 Pre-painted Aluminum (plywood substrate).

- Can be installed over solid substrates, steel decking with polyiso, or in limited applications over open purlins.

- Minimum slope:2/12 – optional factory or field applied side lap sealant.

- Weather Tight warranty optional

- Bold 1 7/8” tall seam

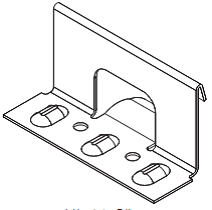

- Special clip allows for full 2″ of thermal movement

Loc-Seam Metal Roof on Large Church

- Many churches choose metal roofing because of its low maintenance and life expectancy.

- Locke Buildings has done several churches, YMCA youth and Christian summer camp roofs.

- Loc-Seam metal roofing is great on pole buildings.

Re-Roof House at Coast

- Metal roofs are very popular at the coast and in mountain areas due to its durability to height and high wind.

- This roof was a complete tear-off. We installed plywood and Loc-Seam with 40 year warranty. This was third job we did for this Contractor. This is his family’s personal coast vacation home.

Wedding Barn Roof

- Locke buildings has done all types of buildings, including this custom Wedding Barn.

- We installed Magna-Rib over CDX plywood.

Windows of all types and sizes

- Windows allow lots of light and create great ventilation.

- When designing a pole building it is a good idea to contact Locke Buildings to verify there are no engineering issues. Much of the time pole buildings sheer strength comes from metal siding. It usually is not a problem but occasionally we may need to move a window or make other changes.

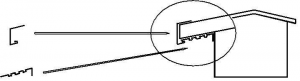

Water Proofing

- Water proofing is very important. If window is not waterproofed correctly it can cause years of headaches trying to fix.

- Locke Buildings has figured out how to waterproof any windows 100% of the time. We guarantee all our windows we install not to leak. And if you install window how we recommend it will not leak either. Locke Buildings provides instructions how to install all our components with all our kits.

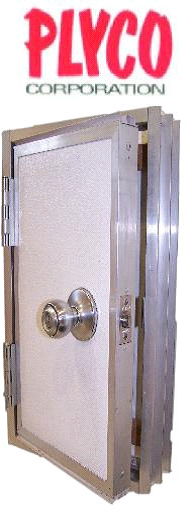

Series 99

- Durable white painted embossed steel skins standard

- High tensile aluminum panel surround with reinforced corners

- for maximum strength

- 3 1/2” Pre-hung 4-way universal swing jamb system

- Optional fixed pin hinges for extra security

- Polyurethane foam core, R-value 9.5

- Comes with keyed lockset, 3 stainless steel hinges, weather stripping and door panel seals included

- 3’-0” x 6’-8” Rough opening: 38 1/8” x 82 1/4”

- 4’-0” x 6’-8” Rough opening: 50 1/2” x 82 1/4”

Series 95 & 94

Series 94

- 24 gauge smooth steel panel, baked-on white enamel finish

- Pre-painted aluminum frame (white)

- Embossed six panel or cross buck design is available in bone white

- Window options available

- 3’-0” x 6’-8” Rough opening: 40 1/2” x 82 1/4”

- 4’-0” x 6’-8” Rough opening: 51” x 82 1/4”

- 6’-0” x 6’-8” Rough opening: 77 3/4” x 82 1/4”

Both series 95 & 94

- 3 1/2” Pre-hung 4-way universal swing jamb system

- Polyurethane foam core, insulating value R-12

- Full perimeter weather stripping

- 3 stainless steel fixed pin hinges

Water Proofing Doors

- Water proofing is very important. If door is not waterproofed correctly it can cause years of headaches trying to fix.

- Locke Buildings has figured out how to waterproof any door 100% of the time. We can teach you!

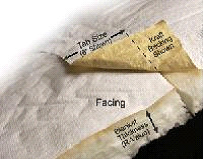

Low – E Vapor Plus and Low-E Foil

- • Saves time and money

- • Non – toxic — No fiberglass

- Seals tight around fasteners

- Certified ASTM testing

- Microcell polyethylene foam construction

- Improve energy efficiency

- Vapor barrier and thermal break all in one

Condensation Control Blanket

- Helps reduce exterior / interior noise

- Eliminates drafts

- Available in cut-to-length

- Allow 1 week notice

Felt Paper

- Manufactured from premium quality organic mat and saturated with high-grade asphalt

- Dimensions: 3’ x 72’

- Approx. weight per roll: 35 lbs

Safe Guard-30 Synthetic Underlayment

- Hybrid technology combines asphaltic polymer & synthetic fabrics

- Slip-resistant

- Meets or Exceeds ASTM D226 requirements

- Thermal stability in excess of 260 F

- Dimensions: 3’ x 145’, 50# per roll

Ice & Water-Shield

- Self-adhesive, glass fiber reinforced, modified bituminous roofing underlayment.

- 250°F temperature rating

- Anti-skid treatment

- Self-seals around nails

- Dimensions: 3’ x 66’, 50# per roll

Clear Span Trusses

- Trusses allow for clear spans up to 100’. (no interior poles)

- Trusses are engineered to snow load at building location.

- Trusses can be designed and engineered for ceiling joists to bottom cord of truss.

Rafters

- Rafters allow for ample head room.

- Ideal for Lean-To’s.

- Great for above loft areas.

Truss Construction

- Quality control.

- Specifically designed to your design and site location.

[yendifplayer video=5]

Many clients choose to add custom eave lights to their project. They add lots of natural light, which many clients find desirable.

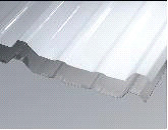

Polycarbonate

- Up to 20% stronger than fiberglass

- 100% U.V. Protection

- 90% light transmission

- Clear as glass . . . won’t yellow with age

- Custom cut to nearest 1 inch increments

- Available in White and Clear

Fiberglass

- 26% U.V. protection

- Allows 66% light transmission

- Great for Sky-lights and decks

- Custom cut to nearest 1 foot increments

One could say that concrete is foundational at the core of every successful building project. What I will say is that if you are interested in a concrete project, from driveways, sidewalks, shop floors, foundations, or any other concrete flatwork, Locke Buildings is your trusted partner to get it done correctly.

Locke Bulding Crew Pouring Concrete

- Pole buildings many times have concrete floors.

- Agricultural buildings can have concrete as well as plumbing and electrical.

- A minimum of 3000lb. strength and 4” for concrete is required. But Locke Buildings recommends 3500lb concrete for extra strength.

- A minimum of 4” thickness is required but based on use, thickness and strength of concrete could be increased. As well wire mesh and rebar are used to reinforce concrete floors.

- Locke Buildings can assist you in better to determine what would be best fit for your application.

56’x40’ Shop Floor

- Smooth finish makes it easy to roll tool boxes around.

- Cure and Seal makes for easy clean up and prevents staining.

Garage With Bathroom Plumbed For Future Apartment

- Plumbing or electrical lines can be installed under concrete.

- Pole building can have bathrooms.

Driveways

- Locke Buildings can remove and replace your old driveway and make the new one stronger.

Sidewalks

- Locke Buildings know how to establish grades for even complex elevation changes and give a beautiful finish.

- We work with home owner from design phase to completion.

Stamped Colored Concrete

- Stamped concrete is available in many patterns and colors.

Cure and Seal

- Cure and sealing concrete creates a shell over concrete which will protect from oil stains.

- If applied directly after pour cure and seal will soak in to concrete making surface of concrete harder.

- Makes for smoother finish for sweeping.

Compaction

- Compaction is critical for concrete stability.

- Compacting should be done in 2-3” layers of rock if using standard plate compactor. It helps to run water on rock you are compacting.

- Locke Building does not recommend using dirt for fill under concrete.

Vapor Barrier Under Concrete

- Black 6mil plastic vapor barrier used directly under concrete.

- The main purpose is to stop moisture from coming up through concrete.

- Locke Building recommends lapping minimum of 24” and taping seams.

- Vapor barrier can increase surface cracking of new concrete. The main reason is concrete needs to cure as even as possible. When vapor barrier is installed moisture evaporating out of new concrete is forced to evaporate through top surface only. It is highly recommended to use cure and seal when using vapor barrier. Avoid pouring on hot days.

Control Joints/ Expansion Joints

- Control joints, or expansion joints are used to control where concrete cracks.

- Locke Buildings prefers to cut control joints. Saw cutting maintains a clean look.

- Saw cutting should be done soon after concrete pour and cut a minimum of 25% of depth of concrete.

- Cutting concrete makes concrete a little weaker and encourages it to crack there. Locke Buildings normally will cut concrete from pole to pole on pole buildings. .

Next Generation.

- Training next generation how to build the Locke Building way. The Old Way- TO LAST!

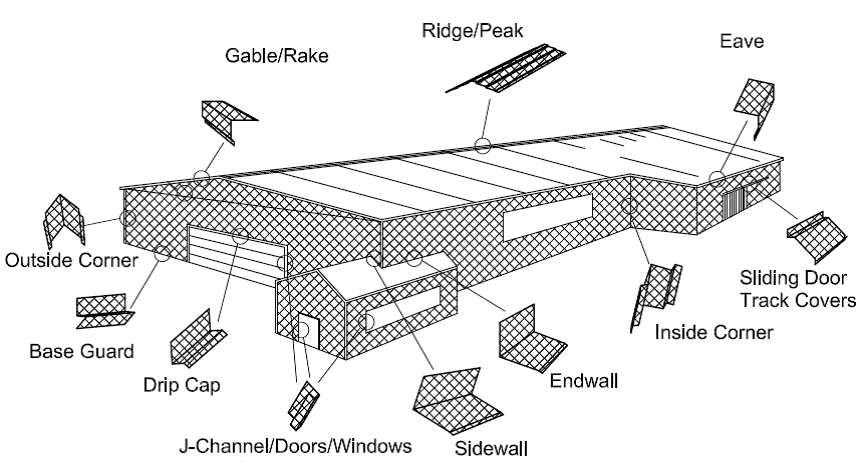

Building trim can either be stock, or can be custom built for your particular application. It can be in a matching or contrasting color. View our metal color chart.

Custom Trim

- Custom fascia trim adds a noticeable finished look.

- Eliminates painting and protects from weather

Overhead Door Jamb Metal Wrapped

- Protects lumber and adds aesthetic value.

- Locke Buildings includes jamb metal wrapping with all our kits and design/build packages.

Rodent Guard Trim

- Rodent guard trim is installed at base of wall metal.

- Blocks off rib spaces in base of wall metal. Eliminating space for little critters to get in.

Fascia & Soffit Parallel Eave

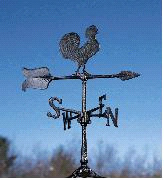

Cupolas/ Weathervanes

- All cupolas are pre-painted 29ga steel construction

- Available in over 100 standard colors

- Optional weather vane

- All metal edges are hemmed

- No need to worry about red-rust

- Roof and sides interlock for weather tight connection

- Shipped Knock-Down, assembles at the job site

- Assembly instructions included

- Our premium flashing kit is now available. It raises the cupola

- 3-1/2″ higher above the peak of the roof, plus it gives the sides a fuller look from the ground

Walls in traditional framed buildings are made out of framed wall studs. Wall boards on a pole building are called girts. Girts are installed horizontally and attach directly to posts. This allows the load to be transferred to the poles. This is main reason pole buildings do not need a traditional foundation, which result in substantial cost savings.

Learn about the different types of girts you can use when building a pole barn or pole building.

Standard Girts

- Girts are commonly framed in two main ways, standard and commercial.

- Standard girt as seen above are nailed flat to the outside of poles.

- Standard girts usually can be installed without cutting boards which saves labor and material.

- If you intend to install insulation or sheetrock you may want to consider commercial girts.

Commercial Girts

- Commercial girts are installed flat and installed between posts.

- Allows for traditional insulation and sheeting such as plywood or sheetrock.

- Commercial girts are stronger than standard girts which allows spacing of poles to be greater than 12’, which can save money by gaining more square foot of building without adding more posts of trusses.

- Commercial girts cost more due to the additional lumber needed for blocking and labor to cut boards to size.

Locke Buildings can help weight the cost of choosing standard vs. commercial wall girts. Sometimes you might only need commercial girts in an insulated office space and can use standard wall girts in non-insulated spaces. Our team is ready to help ensure your pole building project is everything you want!

Pole buildings use purlins, not rafters for main roof boards. Purlins are installed horizontally. Rafters are installed vertically from peak to eve.

PURLINS

- Purlins are sized according to snow load of specific location.

- Commonly 2×6’s are used at 24” on-center with posts set at 12’ apart.

- If posts are spaced further apart or snow load is greater than 25lb., the size of purlin could increase and or spacing could decrease.

- Buildings are specifically designed for each location.

Purlin Installation

- Purlins are commonly installed on top of trusses but can be installed to side of top cord of truss with a hanger.

There are many door options. This section focuses on the large, garage style, overhead and sliding door type options.

Commercial Overhead Door

- Commercial doors are heavier gauge

- Available insulated.

- Seals tight all four sides.

Full View Glass

- Glass adds light and ability to see without opening door.

- Usually much less to add glass to door than installing window.

- Can have glass at any level and multiple panels. Even entire door in glass.

Residential Style Garage Doors with Raised Panels

- Residential style overhead garage doors are used in application where home owner is looking for a more finished look.

- Raised panels with wood grain.

- Available insulated.

Slider Door

- Sliders doors are a good solution for walk or drive areas that need often and easy access.

- Do not need concrete floor like overhead doors.

- Usually less cost than overhead door.

- Built to fit any size opening

- Does not seal air tight.

Dutch Door

- Fabricated from 16 ga. Galvaneal

- Feature one piece cut laser design

- Standard D-Latch

- 3-piece frame prepped with hinges